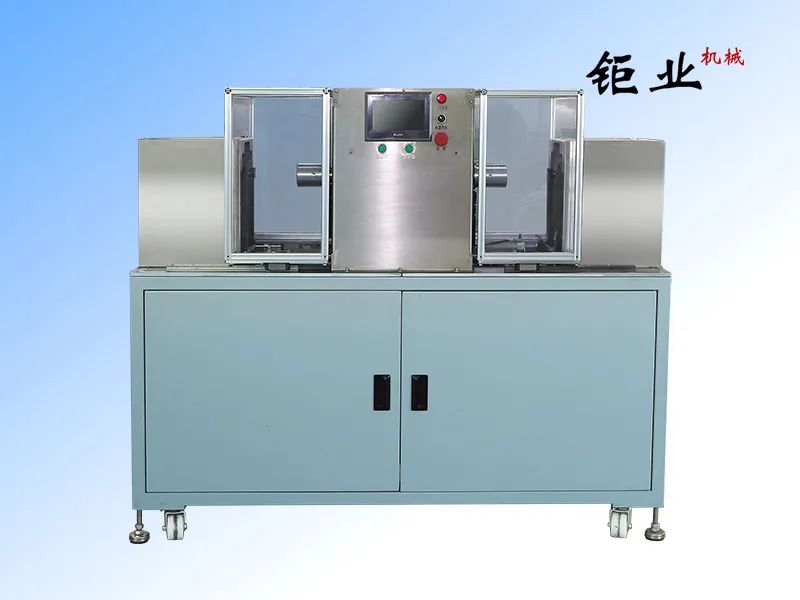

▼ Full-automatic seat machine (liquid)

Machine model: XZB-1000

Mechanical characteristics

1. This machine is used to cut the polarity of the product to 10 mm, then flatten it, insert it into the base plate, measure the ESR, DF, and capacity after the secondary molding, check and confirm the lead foot shape by CCD, put it on the track, transport it to the printing place, clamp the product for printing, and after CCD detection, dry it with a cold light source for charging, testing, and discharging. Then carry out CCD inspection on the warped leg of the positive and negative lead wires, put them into the cartridge, and detect the polarity. A machine for packaging

2. The bare product vibrating plates of this machine are all externally mounted, which is not easy to jam, and the bare product plate base plates are all equipped with automatic feeding devices

3. This machine adopts Omron PLC and Omron human-machine interface, and the alarm display is written, which is convenient to intuitively understand the operation status of the machine

4. Mitsubishi servo drive and high-precision divider are adopted to ensure accurate positioning of the machine

5. The imported Feimengtu tester is adopted, and the CAP tester can simultaneously measure ESR, DF and capacity. This machine is charged at 7 stations and discharged at 4 stations after LC test

6. This machine adopts LED cold light source for drying (the light source lamp bead is lengthened to 175mm), and the curing effect is better

7. This machine has five sets of CCD detection (Kearns and Hikvision), which are respectively used to detect the lead degree, printing and the positive and negative pole warping function after the base plate is formed, and to detect the reverse pole of the cartridge

8. After the product is loaded into the cartridge, it has the negative detection function, and after the number of boxes is completed, it has the automatic cutting function.

Mechanical specifications

Machine name: full-automatic seat machine

Power supply: AC single-phase 220V 50Hz

Machine model: XZB-1000

Machine color: ivory

Scope of application: Φ 4~ Φ 18

Machine size (L * W * H, mm): 2450 * 1700 * 2050

Floor area of machinery (m2): 4.2

Machine weight (kg): 2000

Total machine power (KW): ≤ 4

Air consumption of machine (kgf/cm ²): 4~6

Equipment function parameters

Tensile resistance: average 30-70gf

High foot: the difference between the flat bending point of the guide pin and the size of the finished sleeve base is ≤ 0.18MM

Long and short feet: the difference between the long feet on the base side and the short feet is ≤ 0.30MM

Strength test after flattening the lead: bend and flatten the lead 180 °, which is one round trip, and the two round trip leads are qualified

Printing adhesion: the same product is pasted for 5 times and the printing does not stick off

Machine defect rate: machine defect rate ≤ 0.5%

Electrical configuration

1. Servo: Mitsubishi (2KW, main drive)

2. Main control human-machine interface: OMRON

3. PLC controller: OMRON

4. Capacity tester: FEMTO

5. Leakage tester: FEMTO

6. Industrial camera (monitoring acquisition image contrast mode)

(1) Kearns/Hikvision (seat plate and lead symmetry)

(2) Kearns/Hikvision (print)

(3) Kearns/Hikvision

(4) Kearns/Hikvision

(5) Kearns/Hikvision (cassette reverse detection)

Equipment highlights

1. It can be used to produce vibration-resistant seat plates and vehicle-mounted products

2. Same diameter, convenient height change, no need to replace accessories

3. The four-point test method is adopted to effectively prevent reverse polarity

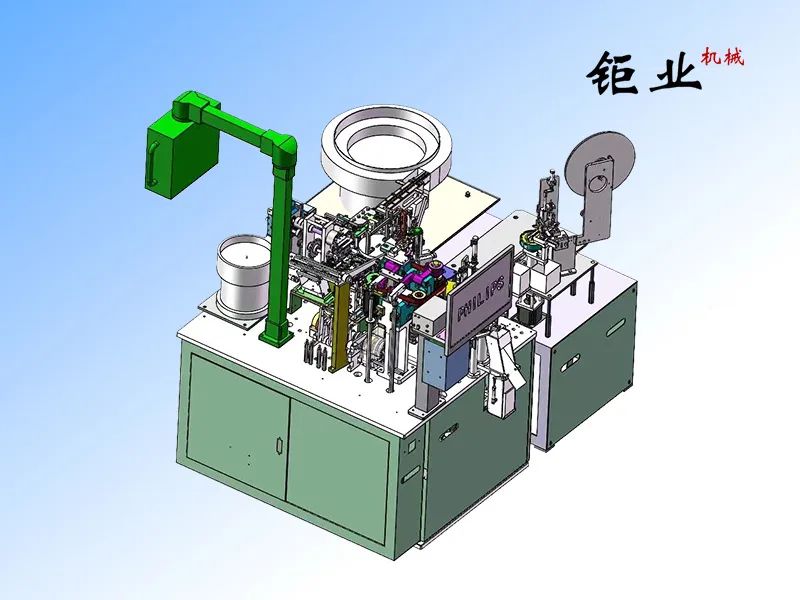

▼ Full-automatic solid-state seat machine

Machine model: XZBH-1600

Mechanical characteristics

1. This machine is to cut the polarity of the product to 16mm after testing and confirmation, use the 16-position round (rotary) disc, then flatten it, insert it into the base plate, measure the ESR, DF, and capacity after secondary molding, check and confirm the lead foot shape by CCD, put it on the track, transport it to the printing place, clamp the product for printing, after CCD testing, dry it with a cold light source, and then charge, test, and discharge it to the 80-position charging disc. The positive and negative lead wires are warped for CCD inspection, and the polarity is detected. A machine for packaging

2. The polarity shall be confirmed by using two stations and four points detection in the reverse direction. If any point is not detected, it shall be considered as defective, so as to ensure that the product has no polarity reversal

3. The bare product vibrating plates of this machine are all externally mounted, which is not easy to jam, and the bare product plate base plates are all equipped with automatic feeding devices

4. Before the LC test of the product, there is a 80-station charging panel that continuously charges without interruption to ensure the charging time of 60 seconds before the LC test of the electrolytic capacitor; Each charging fixture is equipped with power-on indication, the charging PCB is designed in sections, and the maintenance operation is simple

5. This machine adopts Omron PLC and Omron human-machine interface, and the alarm display is written, which is convenient to intuitively understand the operation status of the machine

6. Mitsubishi servo drive and high-precision divider are adopted to ensure accurate positioning of the machine

7. The imported Feimengtu tester is adopted, and the CAP tester can simultaneously measure ESR, DF and capacity. This machine is charged at 7 stations and discharged at 4 stations after LC test

8. This machine adopts water-cooled LED cold light source

9. This machine has five sets of CCD detection (Kearns and Hikvision), which are respectively used to detect the lead degree, printing and the positive and negative pole warping function after the base plate is formed, and to detect the reverse pole of the cartridge

10. After the product is loaded into the cartridge, it has the negative detection function

11. After the boxed quantity is completed, there is automatic cutting of the lower and upper tapes, and the length can be set to wrap the boxed products

Mechanical specifications

Machine name: full-automatic solid base plate machine

Power supply: AC single-phase 220V 50Hz

Machine model: XZBH-1600

Machine color: ivory

Scope of application: φ 4~ φ 18

Machine size (L * W * H, mm): 2550 * 2000 * 2050

Floor area of machinery (m2): 5.1

Machine weight (kg): 2100

Total machine power (KW): ≤ 4

Air consumption of machine (kgf/cm ²): 4~6

Equipment function parameters

Tensile resistance: average 30-70gf

High foot: the difference between the flat bending point of the guide pin and the size of the finished sleeve base is ≤ 0.18MM

Long and short feet: the difference between the long feet on the base side and the short feet is ≤ 0.30MM

Strength test after lead flattening: bend and flatten. 180 ° is one round trip, and two round trip leads are qualified

Printing adhesion: the same product is pasted for 5 times and the printing does not stick off

Machine defect rate: machine defect rate ≤ 0.5% (excluding those caused by refueling and incoming material defect)

Electrical configuration

1. Servo: Mitsubishi (2KW, main drive)

2. Main control human-machine interface: OMRON

3. PLC controller: OMRON

4. Capacity tester: FEMTO

5. Leakage tester: FEMTO

6. Industrial camera (monitoring acquisition image contrast mode)

(1) Kearns/Hikvision (seat plate and lead symmetry)

(2) Kearns/Hikvision (print)

(3) Kearns/Hikvision

(4) Kearns/Hikvision

(5) Kearns/Hikvision (cassette reverse detection)

Equipment highlights

1. It can be used to produce vibration-resistant seat plates and vehicle-mounted products

2. Same diameter, convenient height change, no need to replace accessories

3. Continuous charging mode is adopted to ensure that the charging time of solid products is more than 60 seconds

4. The four-point test method is adopted to effectively prevent reverse polarity

5. Cut the upper and lower tapes separately to save the lower cartridge

▼ Two-station vertical automatic foil brushing machine

Machine model: HX-S450

Mechanical characteristics

1. This machine is used to place the cut aluminum foil vertically on the fixed position of the machine table. The servo motor drives the aluminum foil to rotate. The left and right brushes brush both surfaces of the foil at the same time and absorb dust

2. The human-machine interface is used to control and adjust the speed of the motor. The foil brushing motor and foil brushing time can be adjusted, and the forward or reverse rotation can be set

3. With Mitsubishi PLC control, all faults will be displayed on the human-machine interface, which is easy to operate and maintain

4. It also has two working positions and brushes the foil at the same time, which greatly improves the working efficiency

5. When the rack is brushing the foil, the protective cover is automatically transferred to the aluminum foil storage area, and then the foil is brushed for dust collection. After the foil is brushed, the protective cover is automatically returned

Mechanical specifications

Machine name: double-station vertical automatic foil brushing machine

Power supply: AC single-phase 220V 50Hz

Machine model: HX-S450

Machine color: dark gray

Machine size: length 1630 * width 750 * height 1700

Machine floor area: 2m ²

Power consumption: ≤ 3KW

Applicable range of foil width: 6mm ~ 100mm

Maximum outer diameter of foil: 450mm

Equipment function parameternumber

Speed: 10-15 rolls/min

Fan suction: 180M ³/ H

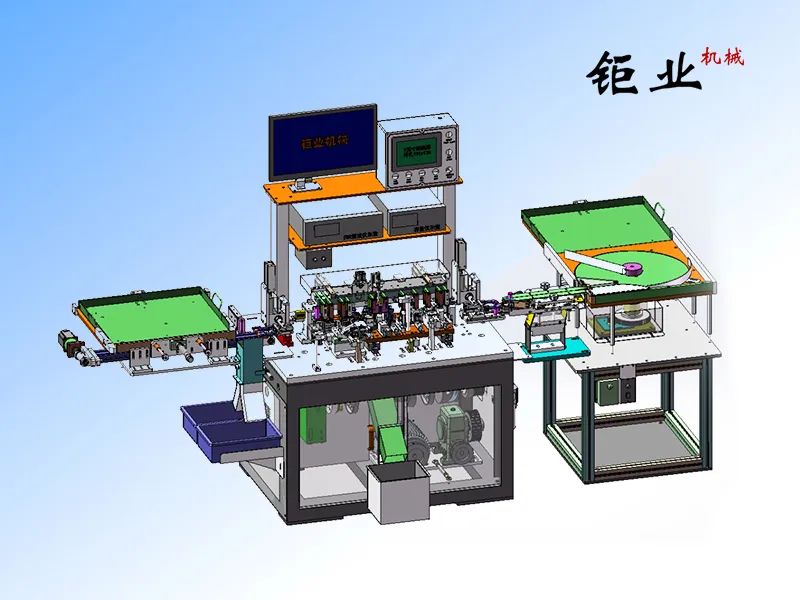

▼ 12-position disc assembly machine

Machine model:JY-120

Mechanical characteristics

1. This machine adopts human-machine interface control, which is easy to operate and has a clear view of information

2. The element is combined with the rubber cover, which is fixed by the rubber cover, and the CP line is pulled to avoid the damage of the pin contact and the poor contact

3. The sealing turntable adopts a splitter mechanism to seal the waist and ensure the sealing consistency

4. After sealing, there is a waist size and convex bean inspection mechanism, which is classified to ensure the quality of good products

5. Advanced CCD vision detection technology is used for waist and convex bean detection

6. The feed of the raw material is equipped with an integral whole foot mechanism

7. The paper pad function in the aluminum shell is an optional mechanism

Mechanical specifications

Machine name: 12-position disc assembly machine

Power supply: AC220/380V 50/60HZ

Machine model: JY-120

Machine color: light green

Scope of application: φ Below 10

Machine size (L * W * H, mm): 1627 * 1285 * 1745

Floor area of machinery (m2): 2.1

Machine weight (kg): 420

Total machine power (KW): 3

Air consumption of machine (kgf/cm ²): 5-6

Equipment function parameters

Transmission positioning error: ± 0.05mm

Prime lead clearance: ≤ D

Machine speed: 50-80 pcs/min

Equipment utilization rate: > 95%

Sealing speed: 1500r/min

Lead guide position error: ± 0.3mm

▼ J-shaped molding machine

Machine model:HXC-150

Mechanical characteristics

1. This machine adopts inverted feeding and discharging

2. Add CCD to detect the foot shape and size

3. Add ESR, short circuit, CAP and detection

Mechanical specifications

Machine name: J-shaped molding machine

Power supply: AC single-phase 220V50HZ

Machine model: HXC-150

Machine color: beige

Scope of application: φ 10~ φ 18

Machine size (L * W * H, mm): 1950 * 1770 * 1850

Floor area of machinery (m2): 3.45

Machine weight (kg): 710

Total machine power (KW): 2

Air consumption of machine (kgf/cm ²): 4~6

Company location: No. 1, Liji Lane, Xiaobian Second Industrial Zone, Chang'an Town, Dongguan City

Switchboard: (0769) 85420118

Contact: 13723559930 Mr. Jiang

15197411699 Mr. Liu

13316620399 Mr. Zhang

Take you into the world of Juye machinery products