| S/N | Content |

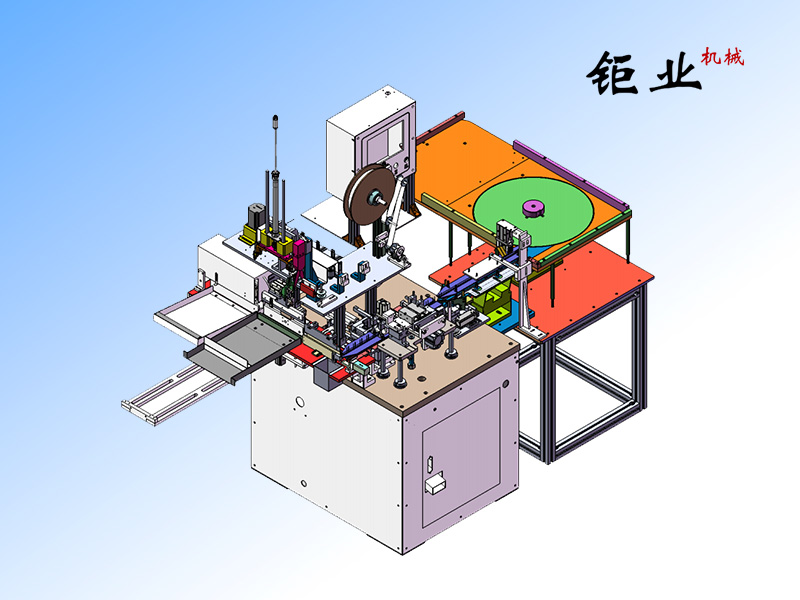

| 1 | Use PLC control |

| 2 | Use the fork structure for product transfer positioning, and simplify the transfer process |

| 3 | The discharge device is set before the product is discharged, and the lead integrity detection mechanism is set during the transfer process, and the defective products are removed |

| 4 | To prevent the conductive bar from not conducting on the two leads, use the folded conductive bar to expand the contact area |

| 5 | The transfer conductive bar is equipped with a conductive bar folding mechanism |

| 6 | The machine adopts human-machine interface operation, and all fault alarms can be displayed on the interface |

| Item | Description | Item | Description |

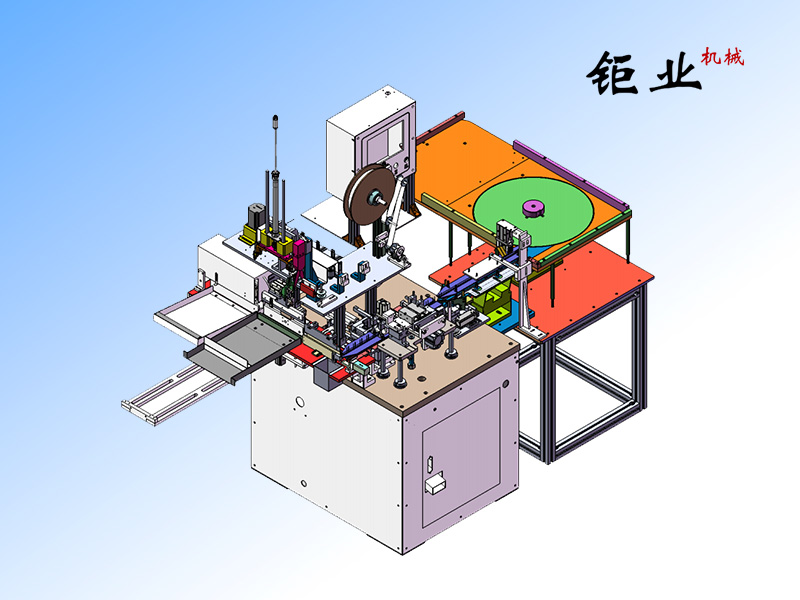

| Machine name | Automatic insertion of capacitor conductive strip into packaging machine | Use power | AC220/380V 50/60HZ |

| Machine model | JY-150 | Machine color | Grey white |

| Scope of application | φ 16/ φ 18/ φ 22 | Machine size (L * W * H, mm) | 2212 * 1080 * 1900 |

| Machine floor area (m2) | 2.4 | Machine weight (kg) | 130 |

| total power of the machine (KW) | 1.2 | gas consumption of the machine (kgf/cm ²) | 4~5 |

| Item | Description | Item | Description |

| transfer positioning error | ± 0.1mm | stretching speed of conductive strip | 20~50 mm/s |

| Machine speed | 30-50 PCS/MIN | Applicable size of conductive bar | 25~50 mm |

| Length of conductive strip | 230-250MM | Allowable deviation of folding | The height difference between the two edges of conductive strip folding is not more than 3mm, which is qualified |