| Serial number | Content |

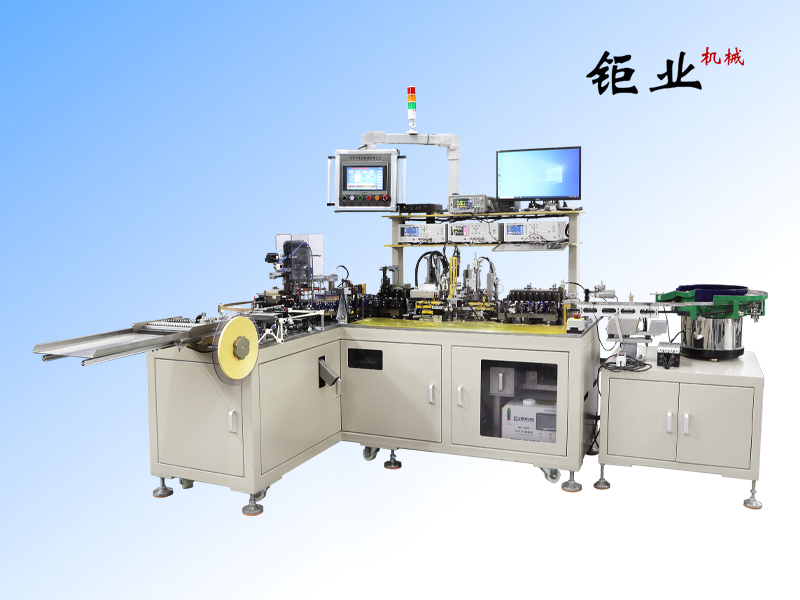

| 1 | This equipment is a fully automatic production device developed and designed by our company based on customer needs and the characteristics of solid-state capacitors. |

| 2 | This equipment perfectly integrates the four processes required for producing solid-state capacitors, including printing, trimming, testing, and ribbon winding, on the same device. |

| 3 | This device has undergone a full foot, polarity detection, and capacity loss testing after being switched back. Then, a four point detection at one workstation is used to confirm polarity. If any point is not detected, it is considered a defect to ensure that the product is not reversed. |

| 4 | The naked vibration discs of this machine are all externally mounted, which is not easy to get stuck, and the naked disc base plates are all equipped with automatic feeding devices. |

| 5 | Before testing the LC of the product, there are 108 charging stations that charge continuously without interruption, ensuring a charging time of 60 seconds before the LC test of the electrolytic capacitor; Each charging fixture comes with a power on indicator, and the charging PCB board is designed in sections for easy maintenance and repair. |

| 6 | This machine adopts Huichuan PLC, Omron or Weikong 10 inch screen human-machine interface, with alarm display text for easy and intuitive understanding of machine operation status. |

| 7 | Adopting Huichuan servo drive and high-precision splitter, the machine achieves precise positioning. |

| 8 | This machine has a reserved ESR testing station, and ESR testing can be optionally selected according to customer needs. |

| 9 | This machine adopts a water-cooled LED cold light source. |

| 10 | This machine has CCD printing detection (Keyence, Hikvision). |

| 11 | This device produces products with height changes, easy to operate, with a height range of 5.5-20mm without the need to replace any accessories. |

| Project | Description | Project | Explanation |

| Machine name | Fully automatic printing, cutting, and charging test Integrated tape machine |

Use power supply | AC single-phase 220V 50Hz |

| Machine model | JY-800 | Machine color | Ivory white |

| Scope of application | φ 4- φ 10 Product height: 5.4 mm-25mm, Cut foot product foot length: 2.5mm-5mm |

Machine size (L * W * H, mm) | Length 2600mm, width 1650mm, height 1650mm |

| Mechanical floor area (㎡) | 4.2 | Machine weight (kg) | 2500kg |

| Total power of the machine (KW) | 4.5KW | Machine gas consumption (kgf/cm ²) | 4-6 |

| Speed | 65-85pcs/min |

| Project | Description | Project | Explanation |

| Charging voltage | 0-160V | Current | 0-2A |

| Capacity tester | Capacity range 0.01pF-9999.9mF Tester accuracy ± 0.1% |

ESR tester | Test range 0.01 ohms 99.999 ohms Test accuracy ± 0.1 |

| LC tester | Test range 0.00-20000uA Test power supply 0-160V/2A |

Polarity detection accuracy | 100% |

| CAP, ESR, LC | Defective products are 100% eliminated | Yield rate | Over 98% (excluding material defects) |

| Serial number | Name | Brand | Remarks | Explanation |

| 1 | Servo | Huichuan | 2KW | Main transmission |

| 2 | Main control human-machine interface | OMRON/Maintenance Control 10 inch Screen | Maintenance control 10 inch screen can remotely modify programs | |

| 3 | PLC controller | Huichuan | ||

| 4 | Capacity tester | To Xin | ||

| 5 | Leakage tester | To Xin | ||

| 6 | Industrial camera (monitoring acquisition image comparison mode) | Keyence/Hikvision | Printing | |

| 7 | Reversing stepper motor | Research and Control, Xinfengyuan | ||

| 8 | Divider | Yuntong, Junmao | ||

| 9 | LED cold light source | DeKoos | Water cooled type | |

| 10 | Instrument/Charging Power Supply | To Xin | ||

| 11 | Electromagnetic valve | Yadeke | ||

| 12 | Main bearing types | NSK/IKO/THK | ||

| 13 | Optoelectronic proximity | Jiazhun/Boyi Jingke | ||

| 14 | Power switch class | Mingwei |