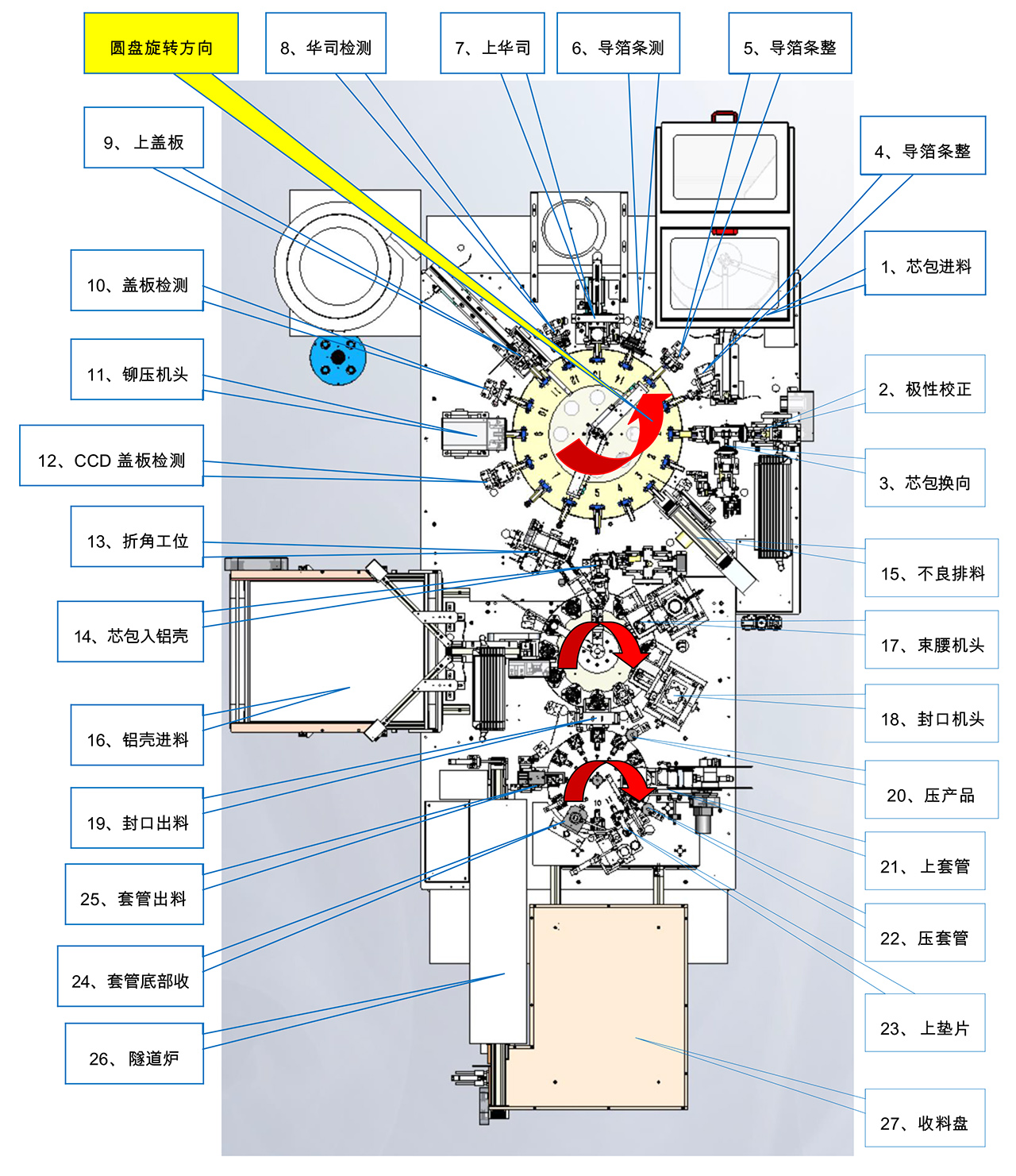

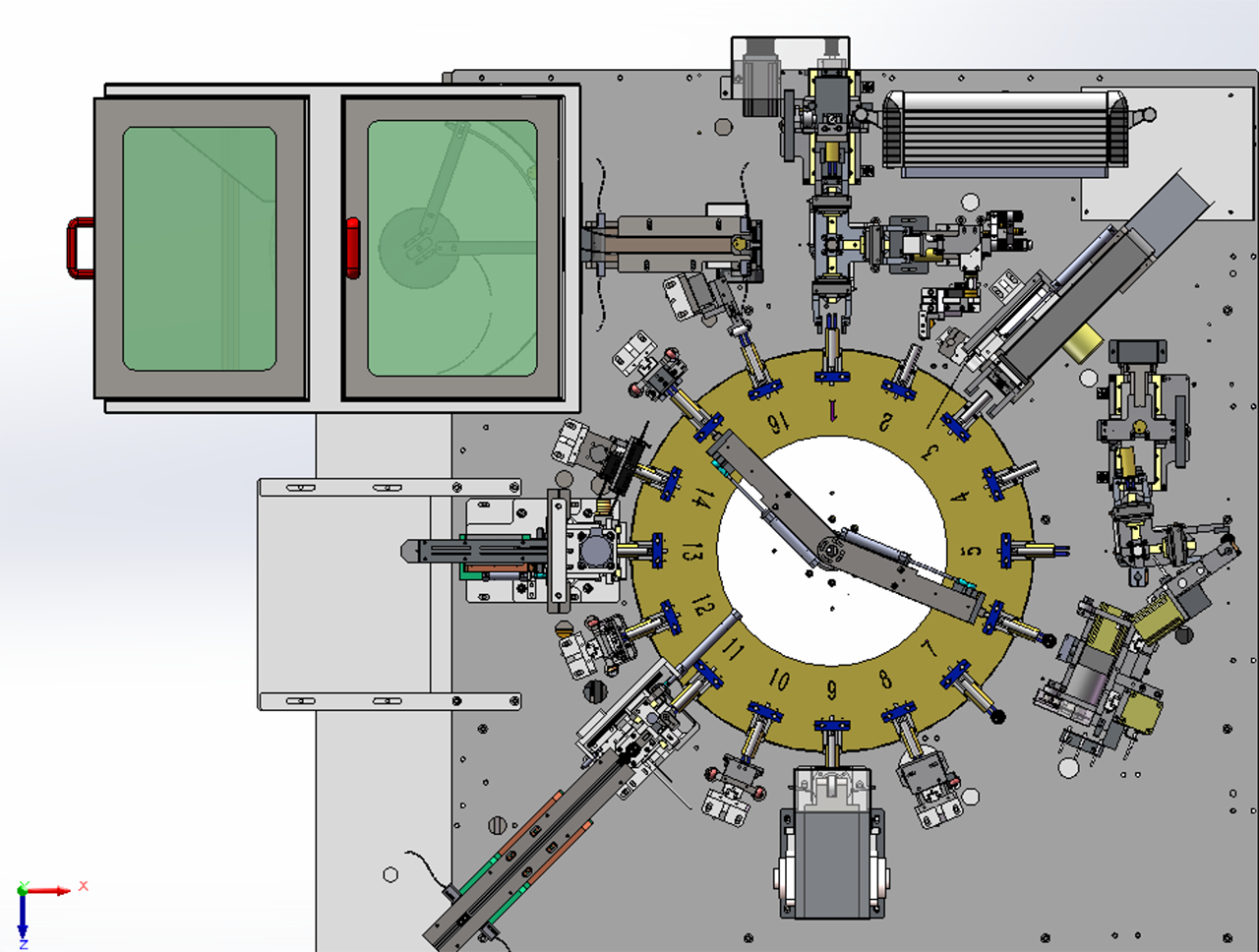

Core feeding station → Core reversing CCD polarity correction station → Film guide strip leveling station

↓

Core and shell trimming station → guide foil thickness measurement station → Shanghuasi station → Huasi detection station

↓

Upper cover plate station → Cover plate detection station → Cover plate riveting station → Guide foil strip Huasi CCD detection station

↓

Corner bending station → Core bud reversing into aluminum shell station.

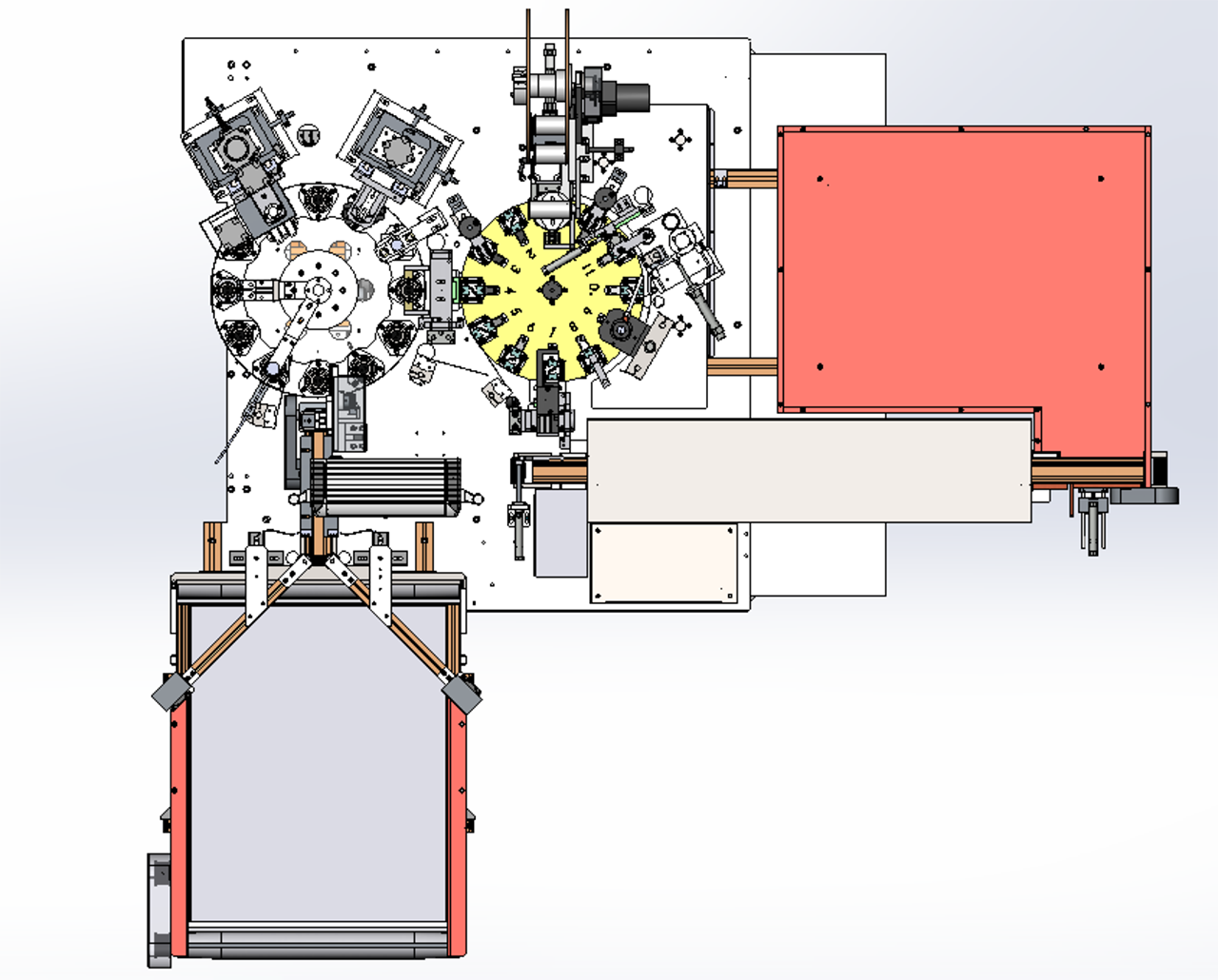

Aluminum shell feeding conveyor belt station → Aluminum shell main disc station → Aluminum shell waist station

↓

Aluminum shell sealing station → short circuit detection station → sealing discharge station → pressing product station

↓

Upper casing station → Compression casing station → Upper gasket station → Bottom contraction station

↓

Discharge flipping station → Tunnel furnace station → Product discharge

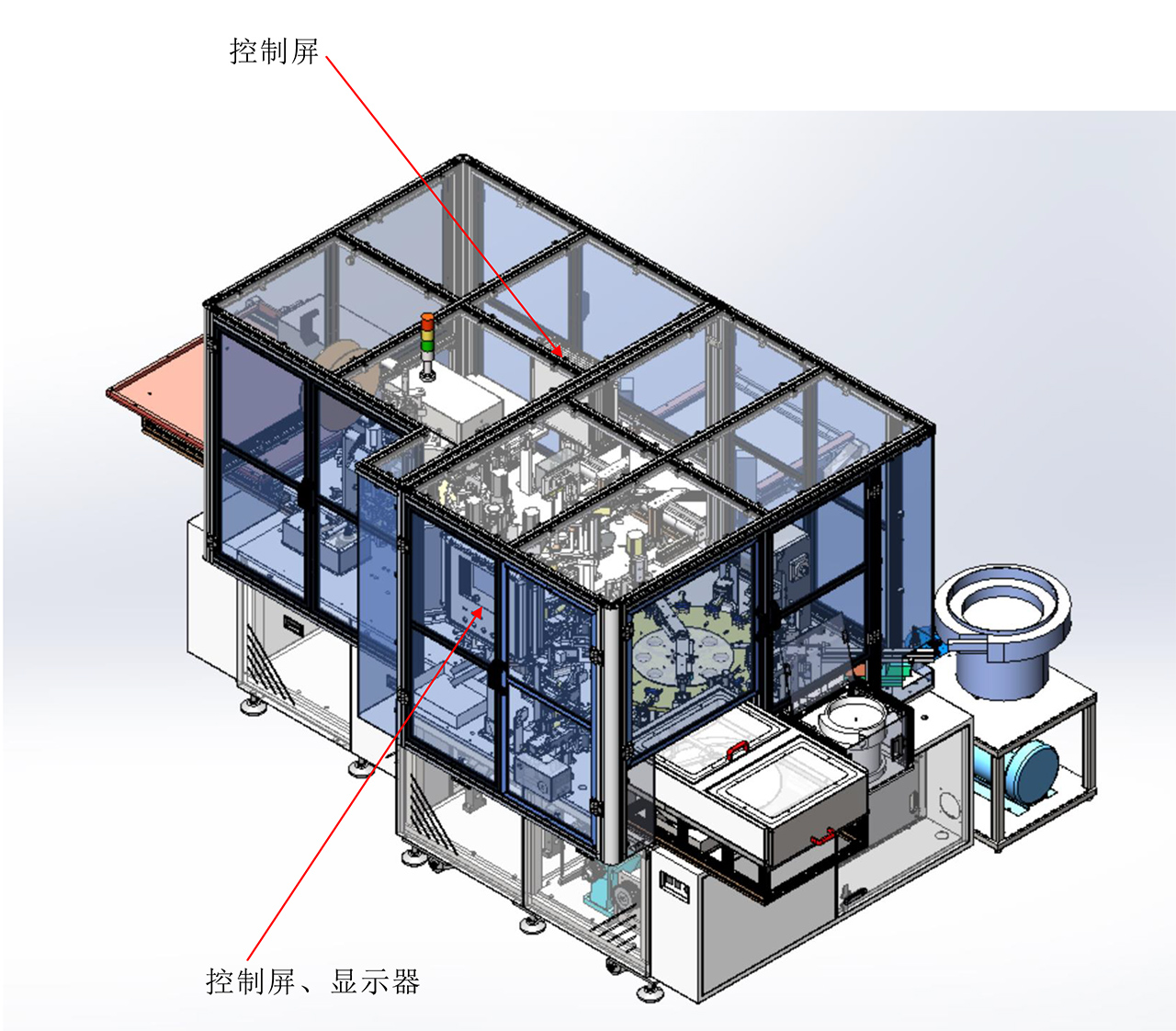

The control screen adopts a maintenance control seven inch screen and a ten inch screen human-machine interface.

| Serial Number | content |

| 1 | This device is a fully automatic production equipment developed and designed by our company based on customer needs. |

| 2 | This device seamlessly integrates processes such as riveting, waistband, sealing, sleeve installation, gasket installation, and engraving. |

| 3 | The device has a short circuit detection station and a reserved ultrasonic welding station. |

| 4 | The bare vibration discs of this device are all externally mounted and not easily jammed. |

| 5 | This device adopts two sets of main drives, making installation and debugging more convenient. |

| 6 | The device adopts Huichuan PLC, with seven inch and ten inch screen human-machine interfaces for maintenance control, and two independent operation boxes. Alarm display cultural characters, more convenient and straightforward; Observe and understand the operation status of the machine. |

| 7 | The equipment adopts Panasonic servo drive and high-precision splitter, which greatly improves the efficiency of equipment production. |

| 8 | This device uses one to two CCD to detect polarity and cover height. |

| Serial number | Name | Brand | Remarks | Explanation |

| 1 | Servo | Huichuan | 1.3KW | Main transmission |

| 2 | Stepper and speed regulating motor | Xinfengyuan | ||

| 3 | Divider | Yuntong | ||

| 4 | Electromagnetic valve | Yadeke | ||

| 5 | Bearing class | NSK/IKO/THK | ||

| 6 | Optoelectronic approach | Jiazhun | ||

| 7 | Power switch | Ming Wei | ||

| 8 | Cylinder | SMC/Yadeke | ||

| 9 | Screw/guide rail | TBI |

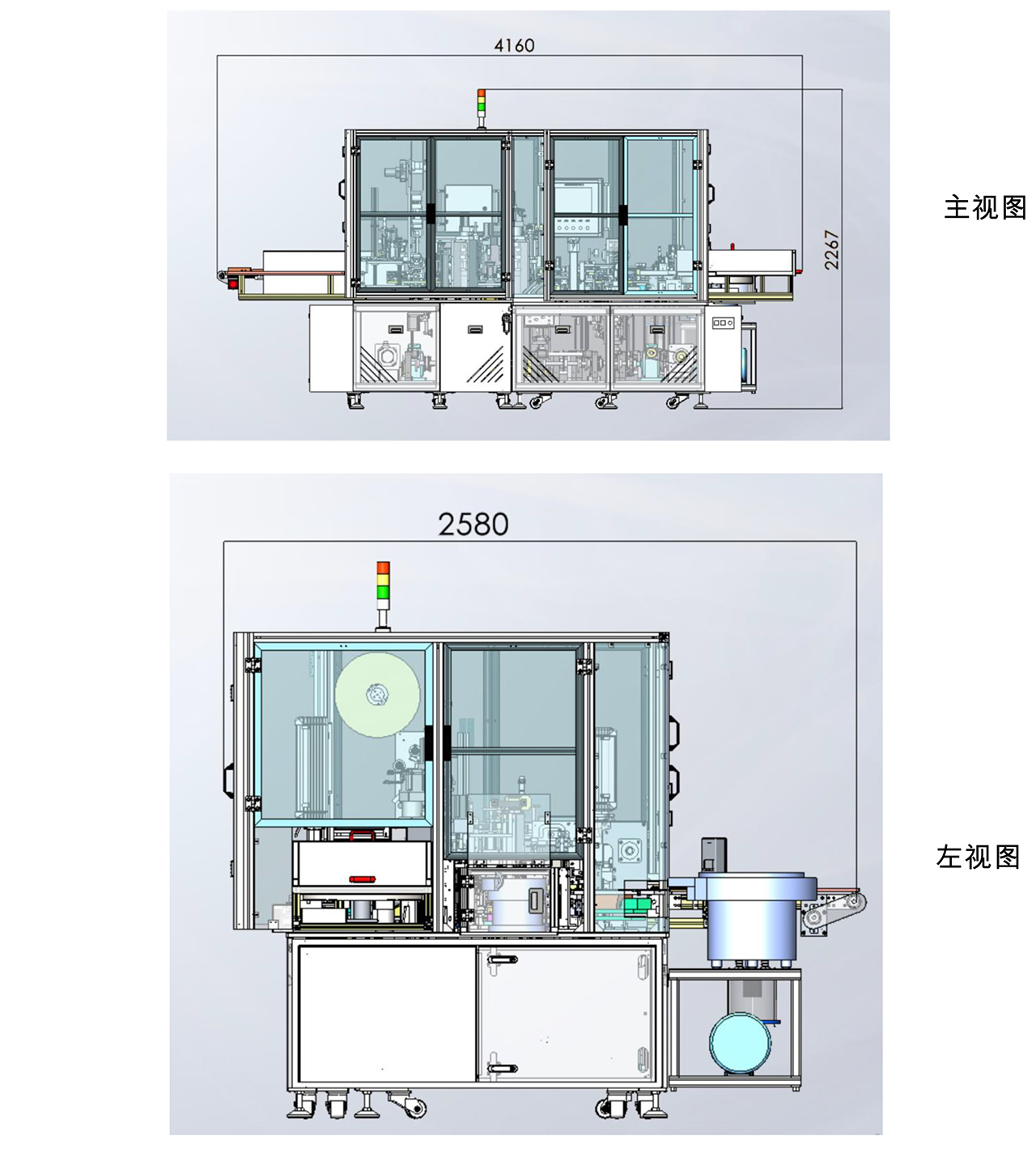

Equipment Name: "Fully Automatic Horn Capacitor Assembly Machine" Model (JY-3500).

Equipment color: ivory white.

The input voltage of the device is 220V, and the input air pressure is 0.45-0.55Mpa.

Equipment production efficiency: 22PCS/Min.

| Diameter Height |

⌀22 | ⌀25 | ⌀30 | ⌀35 |

| 25 | ||||

| 30 | ||||

| 35 | ||||

| 40 | ||||

| 45 | ||||

| 50 | ||||

| 55 | ||||

| 60 | ||||

| 65 | ||||

| 70 | ||||

| 75 |